Gold foil printing is a sophisticated technique that adds elegance and luxury to printed materials. It creates a shiny, metallic finish that enhances the overall look and feel of the design. But how exactly does gold foil printing work? Let’s dive into the details.

The Basics of Gold Foil Printing

Gold foil printing uses a combination of heat and pressure to transfer a metallic foil onto the surface of a material. This heat activates the adhesive on the back of the foil, which then bonds to the material. The result is a bright, reflective design that stands out.

Key Elements in Gold Foil Printing

- The Foil: It can come in various colors, though gold is the most popular.

- The Die: The die is a metal plate that has been engraved with the design or text you want to print.

- The Material: Gold foil printing works on many surfaces, including paper, leather, and plastic.

Hot Foil Stamping Process

Hot foil stamping is a traditional printing technique used to apply metallic or pigmented foil to a surface. It involves the use of heat, pressure, and a metal die to transfer the foil onto the material, creating a stunning, shiny effect. Here’s a breakdown of the hot foil stamping process:

Advantages of Hot Foil Stamping

- Luxurious Finish: Hot foil stamping adds a reflective, eye-catching finish, often used in premium products.

- Durability: The bond between the foil and material is strong, ensuring the design lasts over time.

- Versatility: Works on a variety of materials, making it a versatile choice for packaging, stationery, and branding.

Hot foil stamping is a perfect choice when looking to add a touch of elegance and professionalism to any printed product.

Advantages of Hot Foil Stamping

Hot foil stamping offers several benefits:

- Durability: The foil adheres strongly, ensuring long-lasting prints that resist fading.

- Sharp Details: The heated die creates crisp, clean edges on the foil, enhancing the clarity of the design.

- Luxury Appeal: The metallic sheen adds an upscale touch to products like invitations, packaging, and business cards.

Cold Foil Printing Process

Cold foil printing is another method, but it doesn’t involve heat. Instead, it uses a UV-curable adhesive to apply the foil. Here’s a breakdown of the cold foil process:

Advantages of Cold Foil Printing

- Speed: Cold foil printing is faster than hot foil stamping, making it ideal for high-volume projects.

- Cost-Effective: This process is generally more affordable because it skips the need for heated dies.

- Versatility: It works well on a variety of materials, including those that may not withstand the heat used in hot foil stamping.

Applications of Gold Foil Printing

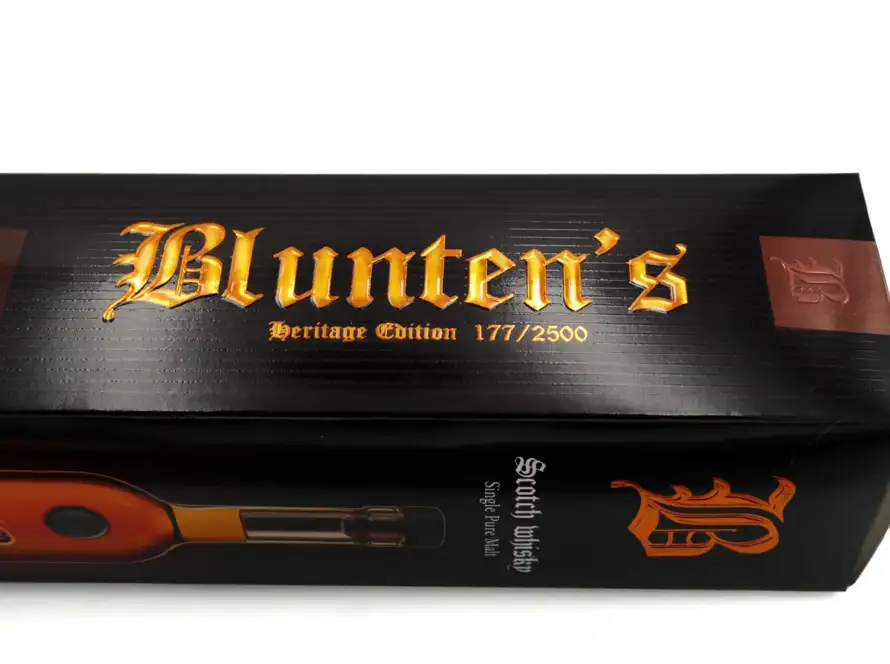

1. Luxury Packaging

Gold foil adds a premium touch to product packaging, making it popular for high-end brands. It enhances the perceived value of the product inside.

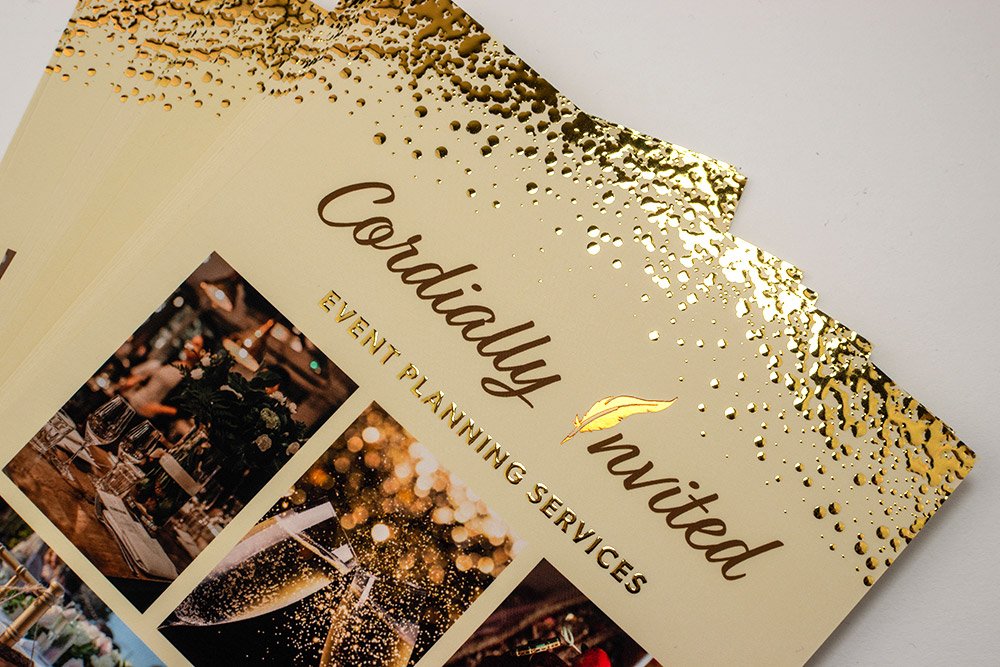

2. Business Cards

Gold foil business cards leave a lasting impression. The metallic accents make your brand stand out, showing a commitment to quality.

3. Wedding Invitations

Couples often choose gold foil printing for their wedding invitations to create a luxurious, timeless look. The shine adds elegance to any design.

4. Certificates and Awards

its used to print certificates and awards. The shiny finish emphasizes the importance and prestige of the document.

Gold foil printing is a remarkable process that transforms ordinary designs into eye-catching, luxurious prints. Whether using hot foil stamping or cold foil printing, this technique offers durability, clarity, and a striking metallic finish. From packaging to stationery, gold foil printing is an excellent choice for anyone looking to elevate their printed materials.